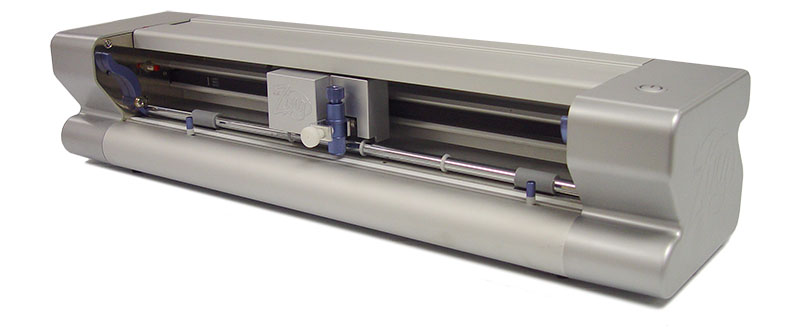

The Accugraphics (Klick-N-Kut) people were kind enough to furnish me with a Zing die-cutter for research and promotional consideration. They had not considered ceramics application for their product, and are curious. The Zing looks like a serious tool. It will cut 14″ wide, and accepts media a bit wider than that. The Silhouette Portrait I wrote about earlier cuts 8″ wide maximum. The Zing has several kinds of registration: you can cut in relation to your image and position the knife starting point manually, you can use a What-You-See-Is-What-You-Get (WYSIWYG), or use the laser beam to register the lower right corner. The Zing works from the Make-the-Cut software bundled with it, and is controlled from that software on your computer (Mac or PC).

My office at home is small, and I am a tool, supply, and books packrat. I have sewing, beading, and knitting supplies, 2 remaining cabinets of slides I’ll either scan or eventually ditch, and loads of books on art, design, ceramics, and computer topics. I also have a scanner, a laser printer (for b & w printing that won’t smear if wet, and laser decals – info on my website handouts page ), and an inkjet printer. The Zing has to be attached to your computer, and you want to be able to see it from your computer screen for moving the registration to the right place before cutting. This meant moving the inkjet to the other side of the room, and making a Wi-Fi connection with it. I had to give up the fax connection to do this. Like the Portrait, the media moves through the Zing, and you need a modest space in front and in back of the cutter.

Unlike the Portrait, the Zing people have done a very thorough manual that’s downloaded or viewed online, and loads of videos about details you need to know on YouTube. They do a good job on educating their users. The Zing comes with a sticky cutting mat, a 45-degree (regular) blade, a 60-degree blade for thick things, a blade holder, a pen (you can also clamp your own pen into the holder) and fillers for the pen. The instructions walk you through set-up, and coach you on practicing with the pen to become familiar with how the cutting set-ups in the software actually locate on the die-cutter, the adjustments, and other details. They kindly say that you have of make a lot of mistakes to learn, you won’t hurt the cutter, and to get in there and TRY a lot of things. The Zing intro online videos are succinct and helpful. You can cut everything from cardstock and vinyl to cake icing sheets, to balsa wood and felt. Someone even mentioned cutting flattened soft drink cans. You can also engrave and emboss, with the associated tools.

I spent much of the day making space for the Zing and setting it up, so I’ve barely scratched the surface with a few pen drawings of arrows to see what they’re telling me about how the various settings deal with where they work on the cutter field. It will take a bit of doing to get past the tech parts, and a bit more to decide how my aesthetic works with this tool, but I’m very intrigued, and glad I have the opportunity to work with the tools.

Nice explanation about how to test the blade depth setting here:

http://www.youtube.com/watch?v=Ws7EwSR-Z-Y

I assume for decal solid color sheets I’ll want to put it on a mat and cut all the way through the color and backing. The video helped me see how I might figure out the right knife depth for that, as it’s thicker than paper, and maybe thicker than cardstock. The Portrait has a ratcheting adjustment for blade depth, while the Zing is infinite, allowing for finer gradations of setting. For something like cutting vinyl, you’d cut through the vinyl, but not the backing – that’s a fine adjustment!

You make adjustments depending on what media you’re cutting to adjust blade depth, speed of cutting, and force. The blade depth is manually controlled, the speed and force set through the software.

Zing FAQs: http://www.iloveknk.com/knk-info/zing-faqs/

If you’re curious about this technology (or just want to see how it works with a cake icing sheet!), do check out some of the videos on YouTube.

http://www.iloveknk.com/knk-info/free-video-tutorials/zing-videos/

Hi, I am thinking of purchasing a ZING cutter. It works with an I-Mac apple computer? I will be using decorative paper sheets are flat and some with fiber pieces and thicker paper…not more than1/8-1/4″ W in the paper. THE PAPER IS NOT FLAT Like CARDSTOCK. What do you think? Can i take an image-small bird and make 20 birds cut-out on a sheet? save time…? Thank-you,Lynn

I’d say ask the Zing people (Accugraphics). They’re usually very helpful and seem to like a challenge. Call or e-mail and inquire. Hope you’ll let us know what you find out.

Linda! I’ve been doing some stuff with full color sheets of decals on a Silhouette… I had good luck with cutting through the decal layer, but not all the way through the paper and putting a bit of vinyl transfer paper on top to hold it all together. I fired the pot with the transfer paper still on, and it burned away nicely. Here’s a little tutorial that I did for Rob Walker’s “Uncollection” website:

http://unconsumption.tumblr.com/post/11577549664/garth-johnson-joins-the-uncollection-using

I think a Zing is in my future… I want to be able to cut keraflex, and I don’t think my Silhouette will quite have the strength. Thanks for alerting me to it!

Heart,

Garth

Thanks, Garth for the info about the decal paper. I thought I’d just put it on a mat and cut through all of it. Do you notice if there’s any affect on the blade? Ceramic materials are generally not kind to cutting edges. I wondered about keeping a blade specifically for decals so there’s still a sharp blade for paper.

The Zing seems to be a good price point for a somewhat stronger tool. The big guys are $800.-1000.00, and I can’t go there. The Zing will do balsa and other interesting challenges, it says, and is a reachable $400.00, and comes bundled with Make-the-Cut software.

We need to talk about what you’re doing with your Silhouette. Thanks for dropping a note!

Linda

The problem with cutting the full sheets of decal paper all the way through is the durability of the decal… I couldn’t slide anything that was intricate with islands off of the decal papers. Whenever the decal is floated in the water and the decal separates from the paper, it becomes too delicate to pick up and apply to a ceramic object.

I didn’t have any problem with the decal paper dulling my blades… but I haven’t been cutting in any quantity.

I actually just ordered a Zing… I’m anxious to try it out with keraflex at my Red Lodge residency later in the month. I’ll keep you posted! I’ve been looking for a cutter that would handle thin wood veneers, chipboard and sturdier materials. I’m really excited!

G

Looking forward to hearing what you think of and do with the Zing.

Thanks for the response about the decals. I have some transfer tape – wonder if that’s like your transfer paper? Came from US Cutter on a big roll. Wonder if I can put the tape on before wetting. Will try later in the week, I hope.

One of the things you’ll enjoy about the Zing is that you can use a setting that cuts in relation to the virtual mat you design on in the software, OR, you can use knife point mode and position your start at the bottom right corner of the material. Very useful for using up smaller scraps of media. I have yet to use the laser positioning, as I’m not doing much print and cut work. Think this is my gateway tool to scrapbooking? I can see me doing birthday cards for all my friends.

Thanks, Garth.

The transfer tape is the same stuff! Just cut your decal, soak it, weed out the stuff you don’t want and apply the transfer tape, and everything should work swell!